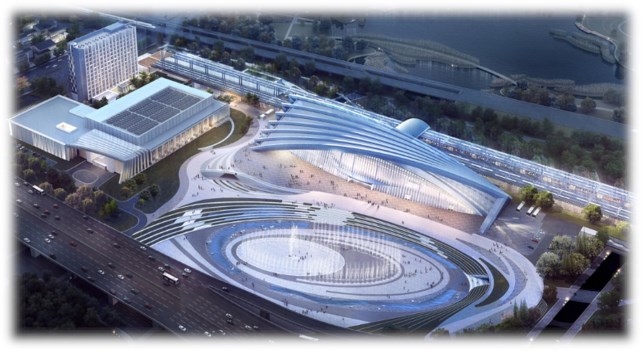

TEMPERED GLASS

Tempered Glass is produced by heating annealed glass in a furnace to approximate softening point then cool the glass quickly and uniformly by blow cool air onto its surface. Uniform compressive stress is formed on its surface, while tensile stress is formed inside, Therefore, it is more resistant to thermal breakage and is capable of withstanding higher wind loads and impact.

HEAT STRENGTHENED GLASS

The process of Heat Strengthening is similar to that of temped glass, however, in this instance the glass is quenched at a slower rate. The result is the glass tension is less than that of the tempered Glass.

STANDARDS

Comply with GB/T 17841 for Coating Glass Standard

Comply with BS EN 1863 European Standard

Comply with ASTM C 1048-18 American Professional Association standards

TEMPERED GLASS FEATURE

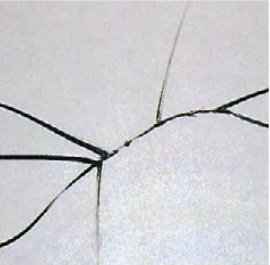

Safety: when broken, it will break into obtuse small particles, which is difficultly hurt people.

High strength: the strength of tempered glass is 4 times that of anneal glass.

Thermal stability: withstanding 200°C temperature difference at least.

HEAT STRENGTHENED GLASS FEATURE

It is obviously superior to ordinary annealed glass in mechanical strength, wind pressure resistance, impact resistance and thermal shock resistance

Low probability of spontaneous break

Better flatness than tempered glass

Non-safety glass

TEMPERED GLASS SPECIFICATIONS

Maximum size:3300~12000mm (130”~ 472 9/20”)

Minimum size:250~250mm (9 9/10” ~ 9 9/10”)

Thickness: 3~19mm (1/8” ~ 3/4”)

HEAT STRENGTHENED GLASS SPECIFICATIONS

Maximum size:3000~6000mm (118 1/10”~ 236 1/5”)

Minimum size:250~250mm(9 9/10” ~ 9 9/10”)

Thickness: 4~12mm(4/25”~1/2”)